Every startup founder knows the crushing weight of bringing an idea to life with limited resources and impossible timelines. Traditional prototyping methods can drain budgets and stretch development cycles beyond what investors will tolerate.

The stakes couldn’t be higher, 73% of successful startups credit rapid iteration as their key differentiator, yet most still struggle with outdated manufacturing approaches that kill momentum and burn through funding faster than they can secure it.

Contents

- 1 Accelerated Product Development Through Custom 3D Printing Services

- 2 Advanced Material Options Revolutionizing Startup Prototyping

- 3 Competitive Advantages of Partnering With 3D Printing Companies

- 4 Strategic Benefits Beyond Cost and Speed

- 5 Emerging Trends Shaping Startup Prototyping in 2024

- 6 Selecting the Right Custom 3D Printing Services Partner

- 7 Implementation Strategies for Maximum ROI

- 8 Smart Prototyping Choices Shape Startup Success

- 9 Your Most Common Prototype Printing Questions

Accelerated Product Development Through Custom 3D Printing Services

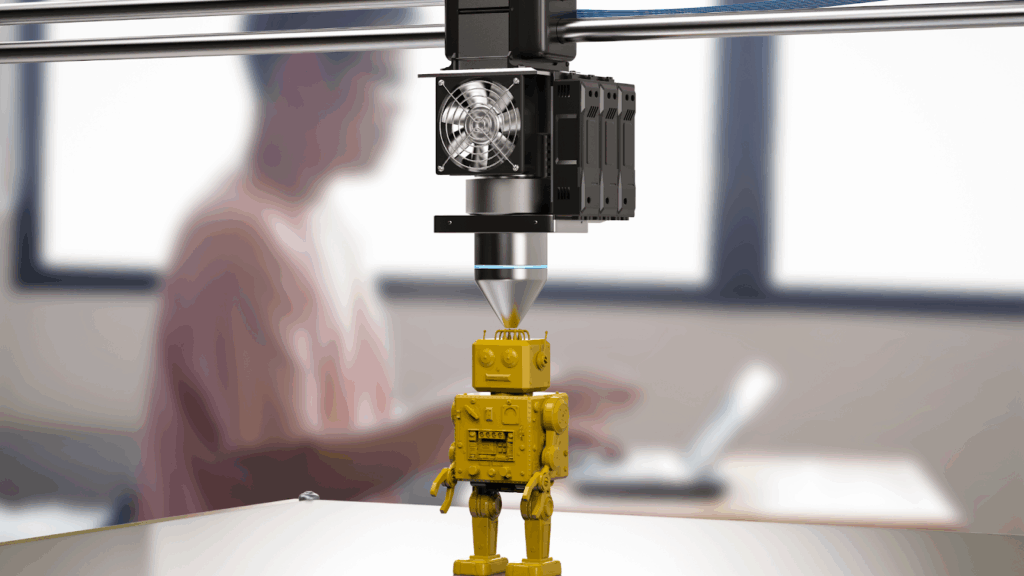

Understanding why modern startups have abandoned traditional prototyping becomes clear when examining the speed advantages. The global 3D printing market is projected to reach $17.5 billion by 2024, reflecting massive industry confidence in this transformative technology.

Forward-thinking entrepreneurs recognize that leveraging custom 3d printing services eliminates the bottlenecks that traditionally plague product development. Instead of waiting weeks for tooling or supplier negotiations, startups can move from concept to physical prototype within days.

Rapid Iteration Capabilities for Startup Success

Speed creates competitive advantages that traditional methods simply can’t match. While conventional prototyping requires extensive setup for each iteration, modern printing technologies allow unlimited design changes without additional tooling costs.

Hardware startups regularly reduce prototype development from six weeks to three days using advanced printing techniques. This acceleration proves critical during investor presentations, where physical prototypes demonstrate viability far better than digital renderings.

Cost-Effective Prototyping for Bootstrap Budgets

Budget constraints don’t have to kill innovation when startups partner with the right 3d printing services for their needs. Traditional injection molding requires upfront investments of $10,000-$50,000 per mold, while printed prototypes cost hundreds rather than thousands.

The math becomes even more compelling when considering iteration cycles. Every design change with traditional methods means new tooling expenses, but printed prototypes adapt to revisions without penalty.

While speed and cost savings drive initial adoption, today’s advanced materials unlock capabilities previously reserved for established manufacturers with massive R&D budgets.

Advanced Material Options Revolutionizing Startup Prototyping

Material science advancements have transformed what’s possible with printed prototypes. Engineers can now specify high-performance plastics, carbon fiber composites, and biocompatible materials that match end-product specifications.

High-Performance Materials for Functional Testing

Carbon fiber reinforced plastics deliver exceptional strength-to-weight ratios for structural testing. Biocompatible materials enable medical device startups to create patient-safe prototypes for clinical evaluation.

Conductive filaments allow IoT and electronics startups to print functional circuit housings with embedded pathways, eliminating assembly complexity while reducing component count.

Multi-Material Printing for Complex Prototypes

Single-material limitations disappear when startups access multi-material capabilities. Engineers combine rigid structural elements with flexible joints in single print runs, creating prototypes that accurately represent final product behavior.

Color-coded prototypes improve user testing sessions by clearly identifying different functional zones. Dissolvable support materials enable complex internal geometries impossible with traditional manufacturing.

Access to cutting-edge materials represents just one advantage—strategic partnerships with 3d printing companies make industrial capabilities available to startups without the need for millions in capital investment.

Competitive Advantages of Partnering With 3D Printing Companies

For startups, speed, innovation, and cost-efficiency often determine who gets ahead in the market. Partnering with a professional 3D printing company can deliver all three, without the heavy upfront investments or long learning curves of building an in-house capability. These partnerships help level the playing field against bigger, better-funded competitors.

By outsourcing to an online 3D printing service, startups can rapidly prototype, test, and refine products while keeping budgets under control. This means ideas move from concept to market faster, risks are reduced, and resources stay focused on core business priorities.

Beyond immediate cost savings, these collaborations open the door to advanced manufacturing methods, expert consultation, and strategic insights that can shape a company’s long-term success.

Access to Industrial-Grade Technology Without Capital Investment

Stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM) technologies each offer unique advantages for different prototype requirements. Startups gain access to all methodologies without choosing a single approach upfront.

Technology access includes emerging methods like multi-jet fusion and continuous liquid interface production, keeping startups at the innovation forefront.

Expert Design Optimization and Manufacturing Consultation

Design for Additive Manufacturing (DfAM) expertise transforms good ideas into printable reality. Topology optimization reduces material usage while maintaining structural integrity, cutting prototype costs and improving performance.

Pre-production scalability planning helps startups understand how prototypes will transition to volume manufacturing, preventing costly redesigns later.

While equipment access and expert consultation provide immediate tactical advantages, the most successful startups use online 3d printing service partners to achieve deeper strategic objectives that impact long-term business viability.

Strategic Benefits Beyond Cost and Speed

Risk mitigation through iterative testing represents perhaps the most valuable strategic advantage. Fail-fast methodology implementation allows startups to identify problems before committing to expensive production tooling.

User feedback integration becomes seamless when prototype revisions don’t require lengthy delays. Medical and aerospace startups particularly benefit from regulatory compliance testing capabilities that traditional prototyping can’t match.

Risk Mitigation Through Iterative Testing

Early problem identification saves exponentially more money than fixing issues after production begins. Startups can test multiple design approaches simultaneously, comparing performance before selecting final specifications.

Customer validation happens faster when physical prototypes enable hands-on evaluation. This direct feedback prevents market misalignment that kills products after launch.

Intellectual Property Protection Strategies

Smart startups establish clear non-disclosure agreements with a trusted 3d printing service online provider, protecting proprietary designs throughout development. Distributed manufacturing capabilities allow startups to spread production across multiple locations, reducing IP concentration risk.

Version control systems track design iterations automatically, creating clear development documentation for patent applications and investor presentations.

As startups master current capabilities for risk mitigation and IP protection, forward-thinking founders are already positioning themselves to capitalize on revolutionary trends reshaping the industry.

Emerging Trends Shaping Startup Prototyping in 2024

Artificial intelligence integration transforms how startups approach design optimization. Generative algorithms suggest improvements that human designers might miss, while predictive failure analysis identifies potential problems before printing.

AI-Powered Design Optimization

Automated support structure generation reduces material waste and improves surface finish quality. Machine learning algorithms optimize print parameters for each specific geometry, ensuring consistent results across complex projects.

These AI capabilities democratize advanced engineering, giving small startups access to optimization tools previously available only to large corporations.

Sustainable Prototyping with Eco-Friendly Materials

Environmental consciousness drives material innovation toward recycled and biodegradable options. Carbon footprint reduction compared to traditional manufacturing appeals to environmentally aware investors and customers.

Circular economy integration allows startups to demonstrate responsible innovation from the earliest development stages.

Understanding these emerging trends is crucial, but success ultimately depends on choosing a partner who can deliver on current needs while adapting to future innovations.

Selecting the Right Custom 3D Printing Services Partner

Evaluation criteria go beyond basic capabilities to include startup-specific considerations. Turnaround time guarantees matter more than maximum capacity for companies needing rapid iterations.

Evaluation Criteria for Startup-Focused Providers

Pricing transparency prevents budget surprises that could derail development timelines. Volume discounts encourage iteration while keeping costs manageable during extended development cycles.

Technical support availability becomes crucial when design challenges arise. Many startups lack internal manufacturing expertise, making consultant access valuable.

Service Level Agreements and Quality Assurance

Dimensional accuracy standards ensure prototypes match CAD specifications within acceptable tolerances. Material certification provides documentation needed for regulatory submissions in controlled industries.

Revision handling policies determine how efficiently startups can implement design changes without delays or penalties.

Choosing the ideal printing partner sets the foundation—now specific implementation strategies maximize return on investment and accelerate time-to-market.

Implementation Strategies for Maximum ROI

Prototype planning starts with clear objectives for each iteration. Design file optimization reduces printing time and material costs while improving success rates.

Budget allocation across multiple iterations prevents overspending on early concepts while reserving resources for refined designs. Timeline planning coordinates printing schedules with development milestones and investor meetings.

Integration with Startup Development Workflows

Agile methodology integration treats prototypes as sprint deliverables, maintaining development momentum. Stakeholder communication protocols ensure all team members understand prototype purposes and limitations.

Version control documentation creates clear development histories for patent applications and technical specifications.

Armed with comprehensive knowledge about current capabilities and future possibilities, let’s address the most pressing questions startup founders ask when implementing printing partnerships.

Smart Prototyping Choices Shape Startup Success

Successful startups build better products and do it faster and smarter than their competitors. Custom printing services provide the speed, flexibility, and cost advantages that modern entrepreneurs need to survive investor scrutiny and market pressures.

The technology has matured beyond simple plastic mockups into a comprehensive development platform supporting everything from initial concepts to pre-production validation. Don’t let outdated prototyping approaches become the bottleneck that kills your startup’s momentum.

Your Most Common Prototype Printing Questions

What makes custom services more suitable for startups than traditional prototyping methods?

Custom services eliminate tooling requirements and minimum order quantities, while traditional methods demand substantial upfront investments that drain startup budgets.

How do online services ensure quality control for critical startup prototypes?

Professional providers maintain certified quality systems with dimensional verification, material testing, and process documentation that meets industry standards consistently.

Can startups protect their intellectual property when using external providers?

Yes, through comprehensive non-disclosure agreements, distributed manufacturing strategies, and careful selection of providers with established IP protection protocols.