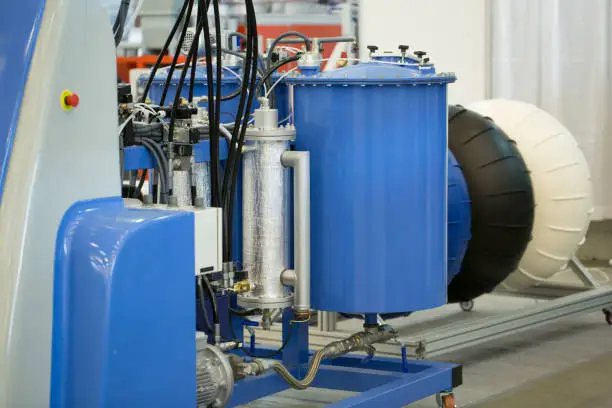

Industrial machinery represents a significant investment for any manufacturing facility, and ensuring it operates efficiently over the long term requires consistent and proactive maintenance. Regular upkeep not only prevents costly breakdowns but also maximizes productivity and operational safety. Whether you are managing polyurethane processing equipment or advanced polyurethane casting machines, implementing the right maintenance practices can help you achieve optimal performance while extending equipment lifespan. By focusing on the right strategies, you can safeguard your investment and keep your operations running smoothly.

Contents

Prioritize regular inspections

Regular inspections are crucial for detecting potential problems before they develop into major issues. Maintenance teams should perform daily, weekly, and monthly checks to ensure all parts are in working condition. For example, monitoring for unusual vibrations, leaks, or wear on moving components can prevent more serious damage. This is particularly important for polyurethane casting machines, as even small deviations in performance can affect output quality.

Keep machinery clean and well-lubricated

Dust, debris, and residue buildup can lead to premature wear and reduce efficiency. Cleaning equipment regularly helps prevent these issues and maintains smooth operations. Equally important is proper lubrication of moving parts to minimize friction and prevent component deterioration. For specialized equipment such as polyurethane processing equipment, following manufacturer’s guidelines for cleaning agents and lubrication schedules ensures long-term reliability.

Replace worn-out parts promptly

Delaying part replacements can result in more extensive damage and higher repair costs. Using high-quality, manufacturer-approved spare parts is crucial to maintain performance and safety standards. In machinery like polyurethane casting machines, replacing seals, nozzles, and other wear-prone components in a timely manner can significantly extend operational life.

Train staff on proper usage

Operator error is one of the leading causes of machinery failure. Comprehensive training programs should cover safe handling, correct operating procedures, and recognition of early warning signs of malfunction. Well-trained staff can reduce downtime, enhance productivity, and ensure that polyurethane processing equipment is used within its optimal parameters.

Monitor and track performance data

Implementing performance monitoring systems allows for real-time tracking of machinery health. By analyzing data such as output rates, energy consumption, and temperature fluctuations, maintenance teams can make informed decisions on when to service or adjust equipment. This approach is especially beneficial for polyurethane casting machines, where precision and consistency are critical for product quality.

Schedule preventive maintenance

Preventive maintenance involves servicing equipment at set intervals to avoid unexpected breakdowns. This includes replacing consumables, recalibrating systems, and conducting thorough inspections. A preventive maintenance plan tailored to your specific machinery type, such as polyurethane processing equipment, ensures minimal disruption and maximum operational lifespan.

Extending the lifespan of industrial machinery requires a proactive approach that combines regular inspections, cleanliness, timely part replacements, operator training, performance monitoring, and preventive maintenance. Whether you manage polyurethane processing equipment or polyurethane casting machines, these practices not only safeguard your investment but also enhance productivity and reduce operational costs. By making maintenance a priority, manufacturers can achieve long-term efficiency and reliability in their operations.